什么是旋转叶泵?

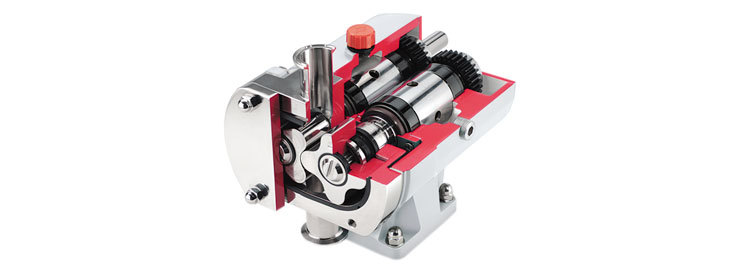

当操作时,凸起的轴在相反方向上旋转,然后重复地产生然后塌陷泵体内的空腔,并将产品从泵的叶片外部的泵的入口移入出口。

由于泵的裂片的运动导致泵放电每旋转的特定量的流体,the pump’s output can easily be controlled by mechanically varying the speed of the pump’s motor, typically with the use of a variable frequency drive (VFD).

由公司制造的不锈钢叶泵阿尔法拉瓦尔和ampco.are widely used throughout the sanitary processing industries.

旋转叶泵的优点

- Since the pump’s lobes do not come into contact with each other, lobe pumps can move solids suspended in slurries (such as cherries or olives in food processing applications) without product damage.

- 温和的泵动作进一步最大限度地减少了产品劣化。

- 可以处理比可以用其他类型的正排量泵泵送的较大尺寸的颗粒。

- May be轻松清洁使用干净的(CIP)或者steam-in-place (SIP)methods, making them ideal for hygienic processing applications.

- Highly efficient for pumping very viscous liquids.

- 提供准确且一致的流体输出,不受头部压力变化的影响,假设足够的流体粘度。

- 通过控制驱动速度可以增加或减小流体流动。

- 如果湿润,旋转叶泵也是如此self-priming, 和can run dry for long periods of time (assuming the pump’s seals are lubricated).

- 一般易于维护。

旋转叶片泵的缺点

- The purchase price of a lobe pump is typically higher than that of other positive displacement pumps, when considered for a particular application

- 由于它们随着电机和齿轮减速器(影响泵的速度和输出)而驱动,因此旋转叶泵具有相对大的占地面积,这可能是一个因素安装。

- The two sets of mechanical seals used in lobe pumps adds to the cost of maintenance and overall ownership.

- The design of lobe pumps requires the use of pressure release and safety bypass valves, adding to their complexity.

- 泵送低粘度流体时,叶泵的效率受到损害。

Getting the most out of your lobe pump’s performance

旋转叶泵为每个操作循环提供定义的流体体积(即,每个转弯的叶片)。The only factor, aside from slip (mentioned later), that determines the amount of fluid being pumped is the speed at which the lobes turn (i.e., the pump’s operating speed, not the motor’s RPMs). Most lobe pumps use gearboxes to increase or decrease the operating speed.

为了计算以给定速度泵送的流体量,泵工程师转向所谓的泵曲线。这些工程计算通常用于确定正排量型泵的性能具有不同类型的液体和不同的操作参数。

通常在泵曲线上绘制两个变量:泵的速度在rpmS和泵在GPM中的输出。在示例图中,请注意,有几条线绘制。这是为了考虑所谓的滑动,在不同的操作参数下的正排量泵中发生的现象。

Slip is the amount of fluid that flows back from the discharge side of the pump to the suction side of the pump during normal operation.

换句话说,滑动是在运行时在泵体内再循环的流体量,并且不会从泵的出口中泵出。

The amount of slip in a rotary lobe pump is determined by two factors,the viscosity of the fluid being pumped and the pump’s differential pressure.由于流体粘度增加,滑动量减小,因为更多的粘性流体不能像薄的流体一样容易地向泵的裂片中的间隙泄压。

然后,随着泵的放电压力增加,滑动将增加,因为泵更易于从泵的吸入侧移动到排出侧和输出的流体。

This is somewhat intuitive, as pressure increases, so will slip. Due to slip, most rotary lobe pump manufacturers will plot multiple lines on a pump curve to show the impact of slip with fluids of various viscosities, and under different pump operating conditions.

In simple terms,泵曲线用于确定旋转叶泵的输出。They help to figure out what size pump is needed to achieve a certain output. A common saying in the pump world is “the displacement determines the pump and the pressure determines the motor." The curve is useful in determining the needed power (i.e., the horsepower required), given the viscosity of the fluid being pumped, the slip factor, and the pump’s discharge pressure.接触CSI.for more help in developing a pump curve for your particular application.

CSI提供的旋转叶泵

There are a number of global manufacturers of rotary lobe pumps, and CSI is proud to represent two companies,阿尔法拉瓦尔和ampco.,为卫生加工应用提供总理产品。它们的旋转叶泵如下所述:

SX系列

Certified by EHEDG,SX泵非常适用于可清洁性和耐腐蚀性至关重要的应用。这些泵还分类为在ADEX指令94/9 / EC组II,类别2和3下的潜在爆炸性环境中使用,具有温度分类T1至T4。

SX泵are capable of flow rates up to 566 GPM and pressures up to 218 PSI.

AMPCO旋转叶泵

AL Series

这些泵的易于维护,CIP性能和具有经济定价的可靠性,适用于各种食品,乳制品,饮料和药物应用。

The铝泵独特的前装密封设计提供更容易的清洁和减少维护时间。流量速率高达230 GPM,压力高达290 psi。

A Guide to Choosing the Right Pump for Hygienic Applications

本指南适用于工程师,生产经理或任何涉及药物,生物技术和其他超清洁应用的适当泵选择的人。

Next Steps

对于食品和饮料和生物制药制造业的卫生加工应用,旋转叶泵可能是泵送高粘度产品的理想解决方案和含有悬浮固体的浆料,没有产品损坏。

然而,由于本文中描述的各种因素可能会影响旋转叶片泵性能,为特定应用开发特定的泵性能曲线是为作业选择正确泵的正确尺寸的关键。

Here, CSI can help.联系我们(417)831-1411讨论您的特定旋转叶泵要求。我们在这里为您提供选择。

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found atwww.xxshagua.com.。